I started with the Grbl v1.1h Configuration and then from UGS ran Machine -> Setup wizard, changing the settings I noted the $ values.

Additional commands I added as Macros are under Install UGS On Pi4

Misc

1 | POS DESC WHY I CHANGED IT |

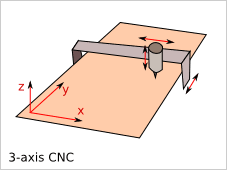

Cartesian – [X,Y,Z] steps/mm

Stepper motor steps:

1 | motor_steps = degrees_in_a_circle / stepper_motor_step_angle |

Driver micro steps:

(typically 1, 2, 4, 8, or 16). Using high microstep values (ie 16) can reduce your stepper motor torque, so use the lowest that gives you the desired axis resolution and comfortable running properties.

1 | microsteps are calculated based on the dip switchs on the stepper drivers |

MM per revolution:

1 | 1605 ball screws for x,y |

Finally some math:

1 | x,y |

Now the resulting GRBL:

1 | $100=320 (x, step/mm) |

Also see grbl settings 101 a how to guide

Rates, Acceleration, Max Travel

1 | POS DESC WHY I CHANGED IT |